Longtime readers will remember that historically, the Richmond Terminal eschews scenic vistas and related stuff.

Some trees have been planted, and there are some profile boards glued to backdrops, and even some ground foam here and there.

Structures haven't been any sort of focus, and until one of the crew built some kits up for me to keep him busy, the railroad was structure-less.

With the rebuild of Crossroads, I planned to have the space for a couple of structures, based on the stock of building kits that I had.

We will dive into one of the builds in this post. This is based on the "Armstrong Electric Motors" background kit. For the Walthers' webpage on this kit, click here.

This is a 3 story, brick building that suggests a WW2 or just postwar style of construction with a loading dock for railcar spotting.

Walthers offers what I will call "standard" structure kits that let you build a "3-D" standalone building, and they also offer background kits that are a "2.5-D" building that is made to snuggle up to your backdrop. The backdrop versions are generally the full kit that is missing a few sprues of parts. This means that you can kitbash or customize what you are going to build fairly easily.

As many building kits don't have the size to properly represent an industry with rail service, combining a few kits lets you illustrate the "mass" of industrial buildings in a space that is less that 2" deep.

Out of the box, the kit is molded in gray plastic, which is pretty dull, but fairly realistic as most industries aren't exactly pretty looking. You can build it to 3 different sizes, width wise, a 2, 4, or a 6 column. If you combine 2 kits, you can get 12 columns, which is what I ended up doing.

I decided to paint the window frames a nice green (Vallejo Air 71-), and then shoot the walls a brown-red (Vallejo Air 71-) mix to make it feel more traditional masonry.

|

| Cutting the frames off the sprue. I dialed the airbrush to "thorough" |

|

| Note the 2 different sizes of frame. |

The kit does include clear plastic to be used for windows. I have to say that getting good results from kit building is somewhat dependent on the tools and techniques that you use. I used canopy glue to glue the windows in, which is the ONLY adhesive you should use for stuff like that. I didn't learn that canopy glue was a thing until I was well into adulthood.

|

| You can see the still wet canopy glue in the corners. |

Once it was all assembled on the bench, I did a QA check and realized that I missed some spots with the airbrush, so I had to use a brush for some touch ups.

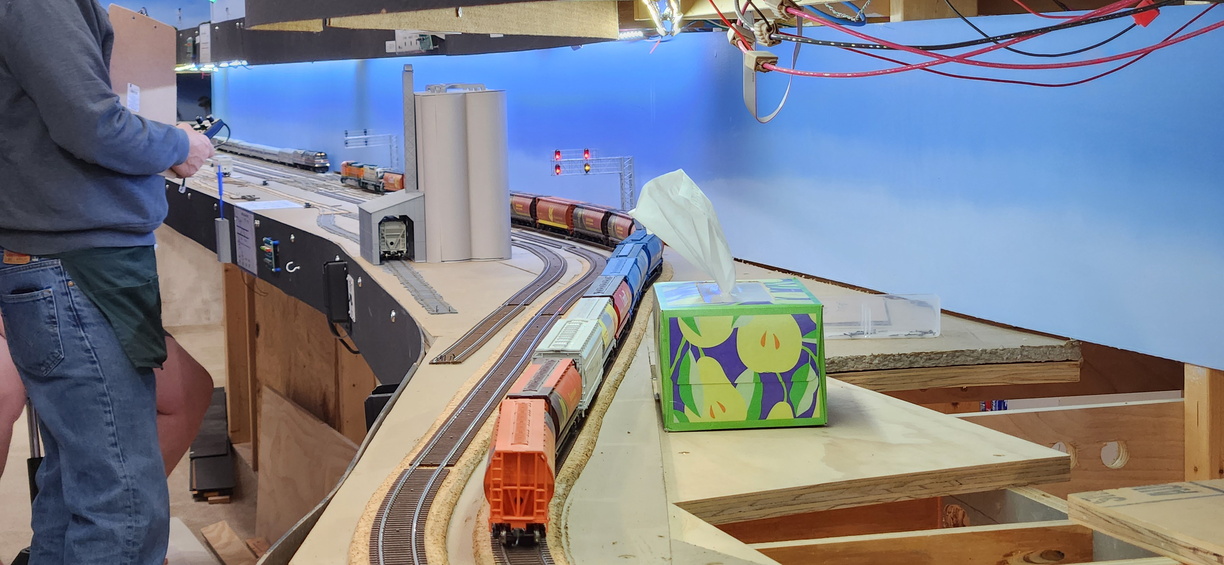

Here's the structure on the layout. I need to add the decaled signs to finish this, but this is a huge upgrade from the little cardboard sign and bare track.